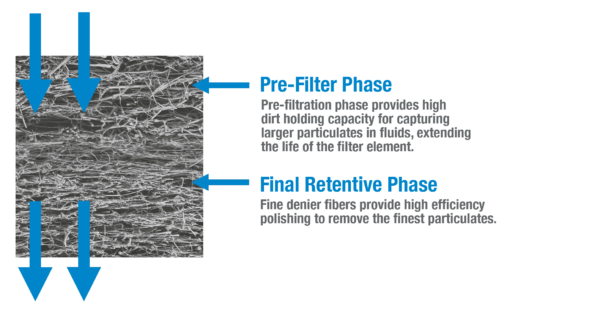

Poor filtration in hydraulic systems can cause contamination levels to rise, thus causing reduced equipment life. Fortunately, TTI offers a line of PowerGuard™ Spin-On Elements with advanced features to fit TTI filtration systems as well as retrofit industry-standard systems. Our PowerGuard™ Spin-On Elements come standard with Dual Phase microglass and an option for water removal in a 5” wide industry-standard configuration. TTI’s Dual Phase media provides superior dirt capacity due to having a built-in pre-filter layer. With broad chemical compatibility and covering a broad range of operating temperatures, TTI’s offerings are an ideal choice for the harshest filtration applications and will meet your operating requirements to guarantee a smooth operation

TTI’s Spin-On Element design is used to clean hydraulic fluids and lubricants in pressurized fluid management systems. In-line hydraulic filters are installed on the low-pressure, return line side of a hydraulic system to clean fluid before it returns to the reservoir. Clean hydraulic fluid reduces contaminant buildup, controls operational & maintenance costs, and maximizes the service life of system components. Spin-On filter elements have an integrated pleated filter element. When the spin-on, hydraulic return line filter becomes clogged with particle contamination, the element is simply unscrewed and replaced with a new element, an integral component of the spin-on element design.

Delivers superior filtration efficiency and dirt capacity with a low-pressure drop.

| TTI PN | – | Micron Rating β1000 | Seal Type |

| TT75S-8 | 1 | B = Buna | |

| 3 | V = Viton (0.17″ Wide) | ||

| 6 | |||

| 10 | |||

| 25 | |||

| 25CWA* |

Not sure which desiccant breather model is right for your system? Try our sizing tool to find the best solution for you.

If you have a competitor product number, we can find the right part for you

Even in the most extreme operating environments, TTI’s Spin-On filter elements will offer superior protection, prevent abrasive particle contamination, and ensure effective long-term performance through a full range of temperature fluctuations. To learn more about how the Spin-On filter elements meet your performance specifications, as well as the wide range of solutions and wide product range we have at TTI for your application requirements, give us a call today at 303-585-0132 or send us a message through our contact form.